Selecting a Brushless DC Motor or Gearmotor

July 31, 2019

1. Determine application specifications for your brushless DC (BLDC) motor.

Several factors should be considered before selecting the appropriate motor for an

application. In addition to speed, torque and duty cycle requirements are other critical

aspects—including the voltage and current capacities for your power supply; whether you’ll

be working with an open- or closed-loop system; and whether velocity, current, or position

control is required. Additional information would include the axial and radial loads on the

motor shaft, what storage and operating temperature ranges are required, and any other

environmental conditions that should be considered.

2. Is your motion a fixed value or variable?

For an application with fixed speed and load, locate the corresponding point on the speed/

torque curve of the motor you are considering and be sure that it falls within the continuous

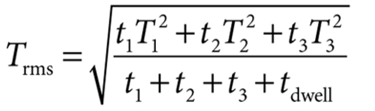

operating range. If you are working with variable speeds and loads, you’ll need to calculate

RMS torque (Root-Mean-Square). RMS torque is a function of time, which varies over the

course of the move profile:

“T” is the torque for a given time increment “t”.

If the result falls within the continuous operating range of the motor, it should not overheat.

Keep in mind that values close to the peak operating limits can only be sustained for two to

three seconds (depending on the specifications of your motor and drive platforms). You’ll

also want to know your peak torque and maximum speed to be sure they both fall within the

operating range of the motor.

3. Decide on what type of motor works best.

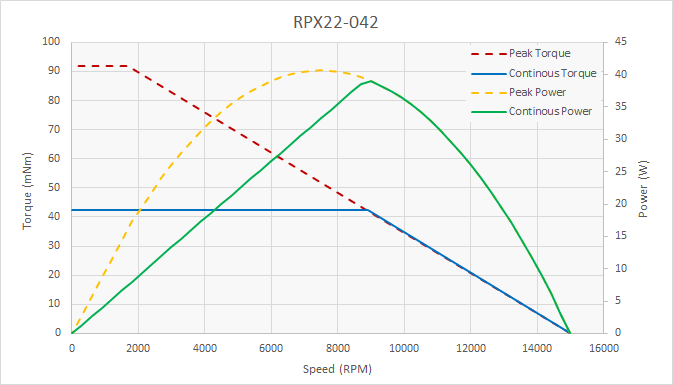

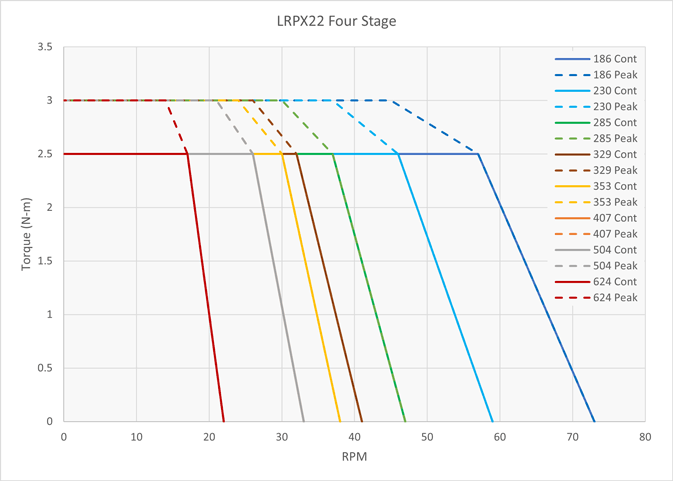

For relatively low-torque and high-speed applications, you can get away with using only

a motor to drive your motion. Coupling your motor with a gearbox, the same motor would

be capable of delivering higher torques at slower speeds. For example, the top drawing

illustrates the speed/torque curve of the ElectroCraft RapidPower™ Xtreme RPX22-042 BLDC

motor, delivering 42 mN-m of continuous torque at 9,000 rev/min, while the bottom

illustrates the same motor that can deliver between 130 mN-m at about 2,300 rev/min

or 2,500 mN-m at about 13 rev/min depending on if it is coupled

with a one-, two-, three-, or four-stage planetary gearbox.

4. Know when a gearbox would be needed.

A gearbox matched with a BLDC motor is the right choice for your application if your torque

requirement is higher than what your motor can deliver on its own, or if your system requires

good dynamic response when there is a significant mismatch between rotor and load inertia

(reflected inertia through a gearbox is 1/(reduction ratio)2. An added bonus to this scenario is

that the motor will be turning faster than the output shaft, resulting in less velocity ripple.

An example of this approach that can reduce overall footprint might be to use an

integrated planetary gearmotor, such as the ElectroCraft

RapidPower™ Xtreme LRPX Series. It is important to remember that the motor-only or

gearmotor decision should not be based solely on speed/torque requirements but also the

type of motion control. For position control applications such as linear actuators,

motor-only may be more desirable. For speed or current controlled applications, such

as pumps or wheel drives, a gearmotor may be more desirable. Physical size, efficiency,

cost, and power consumption all play a part in the decision, in addition to the reasons

mentioned above.

5. Know how to connect your motor to the drive.

Most applications using BLDC motor drives require feedback to correctly sequence the

current in the motor phases. Motors that come with feedback, such as a Hall effect sensor

or incremental encoder, are an ideal choice. In this way a digital driver/controller can be

used in current, velocity, or position control modes. Drives can use Hall effect sensors for

trapezoidal commutation; some drives can also use these sensors for interpolated sinusoidal

commutation.

Alternatively, an encoder can be added for more precise sinusoidal commutation. If the Hall

effect sensor signals are used for velocity loop feedback, there could be significant velocity

ripple at slow speeds. In this case, an encoder would provide more resolution, delivering

better slow-speed performance. In position control mode for a BLDC motor, an encoder is

necessary. ElectroCraft’s CompletePower™ Plus – Universal Drive provides all of the above

control methods for any DC motor type, in a single compact package.

Often design engineers are not motion specialists, in which case contacting the motor (or

motor and gearbox) manufacturer can be a wise choice. Once you understand your application

needs and are close to making a final decision, contact the manufacturer to hone your needs

to your specific application. Their staff has the long-term experience and expertise with a wide

variety of applications and can often help in those final stages.