A Technical Guide to Custom Versus Standard Servo Drives

January 12, 2025

For most motion control applications, a standard servo drive isn’t just adequate — it’s the best

solution. These off-the-shelf units offer a practical balance of proven performance, immediate

availability and straightforward integration, making them the go-to choice for many industrial,

commercial and consumer equipment.

However, certain applications may extend beyond what standard servo drives can deliver. For

example, space constraints may call for varying form factors. Harsh environments may demand

protection levels that exceed standard ratings. Precision motion requirements may necessitate

algorithms tuned specifically to the motor-load combination. In these and other scenarios, a standard

unit simply won’t cut it, making custom drives the optimal solution.

In this white paper, we’ll identify some scenarios and use cases where customization delivers

meaningful value — helping you determine when standard drives suffice and when custom solutions

justify the investment.

Navigating Physical and Environmental Challenges

The drive’s physical operating environment is one factor

that can help you determine whether a standard unit will

work or if you’ll need to go custom. Customization often

becomes necessary when the operating space is severely

limited or when conditions are particularly demanding.

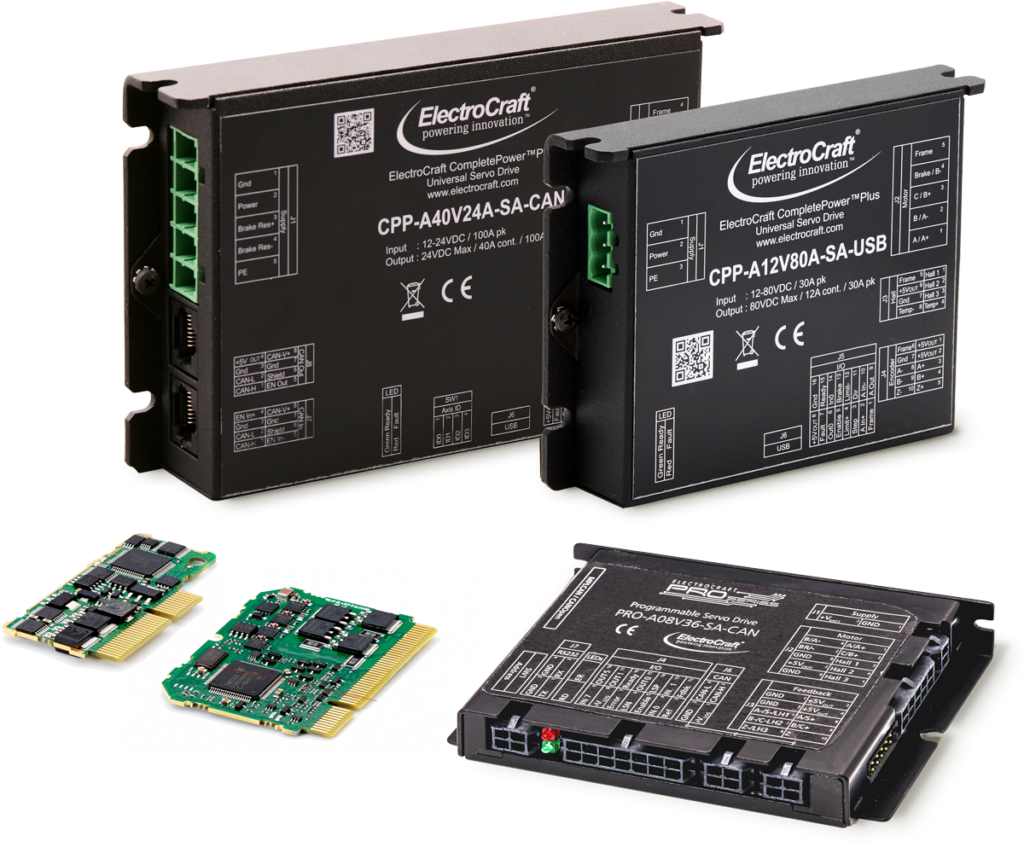

Standard servo drives typically come in panel-mounted or

PCB-mounted formats, which work well for conventional

installations. However, bear in mind that specialized

equipment often has limited real estate for electronics,

making standard shapes or sizes impractical. For high-volume

OEM customers who don’t need all the connectors

and full functionality of a standard enclosed product,

ElectroCraft can supply board-only versions extracted

from standard products. These boards can be paired with

custom heat sinks to achieve the same performance as

standard off-the-shelf solutions but in a smaller package

— a common customization option for cost-sensitive,

space-constrained applications.

Applications requiring an integrated or embedded approach

— where the drive must be integrated directly with the motor

(called a motor-mounted drive) — represent another scenario

of when you may need a custom unit.

with built-in motion control, ElectroCraft has the right solution

to fit your application.

Additional examples include systems that can’t

accommodate a typical rectangular enclosure. In these

cases, you may need non-standard shapes like round

drives that mount directly onto motor backs. And in terms

of packaging, drives can be customized into ultra-compact

PCB assemblies or with adapted standalone chassis

mounts to fit specific enclosure or mounting schemes.

Environmental conditions add another layer of complexity

in the choice to go custom. Standard commercial and

industrial drives aren’t designed for harsh or extreme

operating conditions, such as:

- Applications with extreme heat or cold — e.g.,

ambient temperatures exceeding 100°C or operating

outside standard industrial temperature ranges. - Military and defense systems, which often require

drives that meet MIL-SPEC requirements for shock,

vibration and temperature extremes. - Deep-sea and marine applications, which require

structural modifications to withstand high pressures

at depths reaching several thousands of meters.

Protection against contaminants is another reason for

customization. Drive options range from simple protective

covers and conformal coating for circuit boards, to full

encasement in potting compound for complete

contamination prevention. These design modifications

matter in industries like food and beverage processing,

industrial machinery and agricultural automation.

In one example, ElectroCraft developed an IP69K-rated

drive and motor package for an agricultural application

where up to fifty drives and motors mounted on a tractor

implement automatically control dispensing for each

row in the field. This custom solution involved taking the

standard drive board and motor, creating a new sealed

enclosure and adding waterproof cables and connectors.

The IP69K rating ensures the drives can withstand high pressure

washdown, in addition to custom hardware that

can withstand the extreme vibration and temperature

ranges often encountered on farms.

Another example involves a custom drive integrated

into a joystick with force feedback (haptic) capabilities

for a steering system. The drive had to meet MIL-SPEC

requirements for shock, vibration, temperature and

ingress protection, which required a conformally-coated

drive board in a sealed package.

Matching Power Delivery to Motor and Duty Cycle Requirements

The motor’s duty cycle and size may require power

delivery specifications that fall outside the range of a

standard servo drive. Because standard servo drives offer

fixed ranges of operating voltages and output currents,

precisely matching the power source to a specific motor

often requires a custom unit. If an application needs

current or voltage levels beyond standard specifications —

for example, an output between the continuous currents

of standard models or a specific voltage for efficient

operation — custom drive solutions may be necessary.

ElectroCraft can customize drives for any voltage

or any wattage within the platform’s capabilities

and any reasonable current level. Standard

offerings are scaled at 6A, 12A, 24A, 40A and

50A continuous, with the largest drive capable

of 100A peaks, but end-users requiring specific

current ratings between these values can request

custom configurations.

One recent customization request came from a large OEM

in laboratory diagnostics. The company needed a drive

to control a NEMA 34-frame BLDC motor in a low-current

application — only 3 to 4A. In addition, the specification

also called for a universal AC line input capability; the drive

needed to accept 85 to 265V AC anywhere in the world

and convert it to DC to run the motor without any jumper

settings or physical adjustments.

The customized solution included an integrated power

factor controller that reduced harmonics on the AC line

while allowing operation at universal voltages — similar to

a laptop power supply. This system eliminated the need

to size electronics according to the highest voltage (220V)

when using 120V, which traditionally meant paying for

the higher voltage capability. The power factor controller

draws current in phase with the line voltage, producing

constant DC power to run the motor at the appropriate

stepped-down voltage.

Other important factors are duty cycle and torque

requirements. High-acceleration applications —

sometimes called pulse-duty operations — demand

substantial peak current to generate the peak torque

needed for rapid starts and stops. ElectroCraft’s drives

typically allow peak current values that are double the

continuous rating for a couple of seconds, which is

useful for quickly accelerating heavy loads. The drives

automatically limit current and reduce performance until

operation returns to the continuous range, preventing

thermal damage. If the required peak current and

continuous current exceed what a standard drive can

handle, a custom solution becomes essential to prevent

overheating and failure.

Managing Regenerative Braking

Applications requiring regenerative braking represent

another scenario where standard drives might not suffice.

When motors decelerate under load — common in

robotics and electronics manufacturing — they generate

energy that flows back into the drive. Many standard drives handle this with an onboard shunt regulator that

dissipates the excess energy as heat to keep DC bus

voltage safe.

Standard drives have fixed limits for how much

regenerative power their internal shunt can handle.

Applications with high-inertia loads or vertical axes, like

elevators or gantries where gravity assists downward

motion, can generate more power than a standard shunt

can dissipate. When the regenerative continuous or peak

power exceeds these built-in limits, a custom drive with

enhanced capabilities or a standard drive with an external

shunt resistor module becomes necessary to safely

handle the additional energy and prevent drive damage.

Tailoring Control Algorithms for Specialized Motion Profiles

Standard drives come with pre-configured algorithms

that work well for typical applications. For example,

standard ElectroCraft drives include Advanced Field

Oriented Control (FOC) for brushless and closed-loop

stepper motors, delivering good dynamic response

and acceptable torque ripple for most use cases. The

Universal Drive can run brushed DC, BLDC and stepper

motors with the unique ability to control steppers as

if they were brushless motors using FOC. This feature

provides both cost and mechanical advantages; BLDC

motors tend to have longer, skinnier form factors while

steppers are shorter and wider, giving designers greater

mechanical flexibility when space constraints vary.

Additionally, built-in motor databases and preconfigured

settings allow you to complete most configurations in

seconds, with auto-tuning handling basic optimization.

For applications requiring standard velocity control,

torque control or basic positioning, these algorithms are

more than sufficient.

Customization often becomes necessary when the

motor-load combination has characteristics that standard

tuning can’t accommodate, necessitating custom control

algorithms and feedback processing. For example,

applications requiring smooth motion at low speeds,

minimal torque ripple or precise tracking may need

highly specialized parameter tuning. In these use cases,

ElectroCraft can develop custom-tuned FOC algorithms

specifically matched to the motor’s electrical characteristics

and the application’s performance requirements.

The choice of commutation method also factors into

customization decisions. ElectroCraft can implement

simple trapezoidal commutation for cost-sensitive or

basic applications, or deploy more advanced sinusoidal

commutation with custom FOC algorithms when

applications demand both high efficiency and superior

control resolution.

Integrating Non-Standard Feedback Devices

Another factor for customization involves the use of

feedback devices. Standard drives work with common

encoders and sensors using industry-standard interfaces.

These units typically support Hall sensors for commutation

and optical encoders for speed and position, along with

Sin-Cos encoders, magnetic encoders, various serial

encoder protocols and other feedback types through

selectable drive parameter settings.

When applications use proprietary position sensing

technology or non-standard feedback devices, however,

it’s important to customize the drive to correctly accept,

process and communicate those specific signals.

Similarly, while standard drives provide basic fault

diagnostics, custom versions can be configured to

monitor and report specific internal functions like following

error or other application-critical parameters.

The Power of Custom Software

In the semiconductor industry, an inspection

station required positioning accuracy within 50

microradians of the commanded position for

precise instrument alignment — a resolution that

no encoder could directly sense. ElectroCraft

developed a unique algorithm using software

interpolation to control the torque vector in the

motor, maintaining accurate positioning.

Because the application used a small motor,

engineers rescaled the drive’s voltage and current

feedback to maximize resolution. Starting with a

standard 48V drive with 16-bit PWM, engineers

dropped the voltage to 12V, making each PWM

step four times smaller. They also reduced the

current measurement range from 10A to 500mA

full-scale, spreading the finite digital resolution of

the analog-to-digital converter across a narrower

range to increase feedback resolution and fidelity.

ElectroCraft later adapted this same fine-resolution

technology for another use case — a

vinyl turntable manufacturer. The tight control

enabled detection of flaws in master discs by

virtually eliminating wow and flutter.

Bridging Communication Gaps with Custom Protocols

Beyond modifications to the drives themselves,

customization also addresses how servo drives

communicate and integrate with broader control systems.

Servo drives need to integrate into larger, often complex

communication networks and system architectures, with

standard units supporting common industrial protocols

like CANopen® or EtherCAT®. Applications that require

integration with unique, specialized or proprietary

networks outside these standard offerings may demand a

custom solution.

ElectroCraft has extensive experience creating custom

serial-based control protocols (RS-232 and RS-485)

when standard interfaces can’t meet an application’s

requirements. This capability is particularly valuable for

integrating drives with legacy equipment or when a new

accessory must work in harmony with existing systems

using proprietary communication schemes.

Further, in distributed control systems where drives

are located closer to motors, custom features enable

the drives to function as intelligent nodes capable

of electronic gearing or executing motion-trajectory

calculations for tightly coordinated or synchronized

axes. These features are important in many industrial

automation, medical and lab equipment and

semiconductor processing applications, which require

advanced control.

Built-in Protection: The Move From Custom to Standard

ElectroCraft builds comprehensive protection into

standard products as a matter of good engineering

practice. Based on years of customization

experience, these features have moved from “nice

to have” custom requests to standard offerings.

For thermal protection, all standard servo

drives include over-temperature monitoring

with customizable and adjustable temperature

threshold parameters. Drives also support motor

thermistors, with selectable drive parameter

settings to accommodate a variety of thermistor

types. Integrated I²t (current-squared-time)

protection calculates accumulated thermal energy

to prevent motor damage — a standard feature in

quality drives.

Current protection works similarly. Drives

support both peak and continuous current

limits, automatically clamping current and

reducing performance until operation returns

to the continuous range. While users can adjust

these thresholds, the fundamental protection

mechanisms are built into standard products.

ElectroCraft drives also include built-in

electromagnetic brake control — a feature that

many vendors don’t offer but that proves essential

in vertical-axis and safety-critical applications.

Customizing I/O for Enhanced Functionality

Custom I/O is perhaps one of the most frequently

requested customizations. In these use cases, custom

drives often include modified firmware to add functions

to I/O, such as inverting inputs, providing an indicator

status or reporting feedback based on control variables.

In one example, ElectroCraft created a drive that could

be pre-configured to select one of eight configurations

automatically based on I/O pin states. Using a custom

harness that tied specific pins to ground, the drive could

detect and load the appropriate configuration, eliminating

manual setup steps.

Making the Decision

Standard servo drives work well when your application

fits within typical voltage, current and environmental

ratings, requires basic control functionality and uses

common form factors and protocols. Custom drives often

become necessary in applications with space constraints,

harsh environments, demanding power requirements,

ultra-precise motion control, non-standard interfaces or

advanced features like haptics.

For high-volume OEM customers, customization

especially makes sense. Buying larger volumes of drives

justifies the development effort, resulting in optimized

solutions at a lowest cost per unit. You also avoid paying

for unnecessary features while gaining precisely tailored

capabilities.

Because standard products serve as an excellent

jumping-off point for custom solutions, we recommend

starting with standard off-the-shelf options to test

and validate performance requirements. If you find

the standard drive performs well but needs additional

features or modifications, that’s the ideal time to explore

customization. This approach reduces risk by proving the

basic concept before investing in custom development.

To learn more about standard and custom servo

drives, please visit: www.electrocraft.com.