November 19, 2025

DC motor drives are used to control small frame motors for a wide variety of applications such as medical and laboratory equipment, semiconductor processing machinery, precision robotics and more. Depending on the application, different types of control methods can be used in combination with various levels of drive sophistication. This article describes two-quadrant versus four-quadrant operation and why one would be selected over the other.

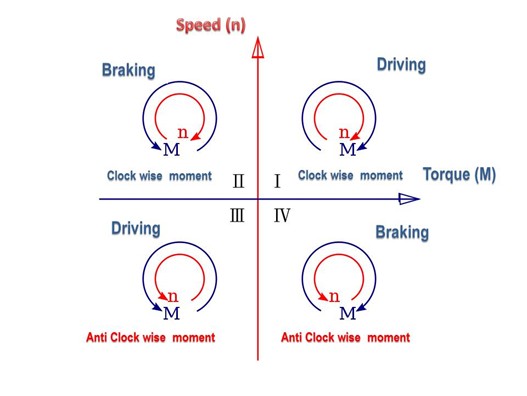

There are up to four quadrants of operation for DC motor drives: forward motoring (I), forward braking (II), reverse motoring (III) and reverse braking (IV). In other words, the motor can either be converting electrical energy into mechanical (motoring) energy, or mechanical energy into electrical (braking) energy.

Certain applications, such as simple fans or pumps typically require only two-quadrant operation, driving the motor in either direction, clockwise or counter-clockwise, but with no braking. A simple two-quadrant drive is typically more affordable, takes up less space and is much simpler to configure.

More complex and precise motor control applications, such as multi-axis robotic arms, generally require four-quadrant control with both driving and braking in either direction, clockwise or counter-clockwise, where current can flow both to and from the motor.

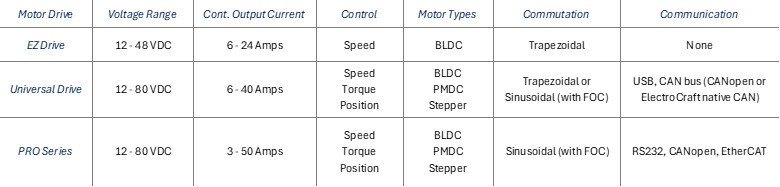

ElectroCraft offers three distinct motor drive families with two-quadrant or four-quadrant operation for precision speed, torque and position control. The motor drives serve a range of brushless direct current (BLDC) motors, hybrid stepper motors and permanent magnet direct current (PMDC) brush motors.

ElectroCraft motor drives are designed to offer a valuable combination of cost-effectiveness, ease of use and wide operating ranges, serving a massive array of motion control use cases. Table 1 refers to three different drive families, each offering several different models with a wide range of voltage and current combinations while protecting downstream equipment with built-in short-circuit, overcurrent, overtemperature and overvoltage protection.

EZ Drive

This affordable, entry-level drive utilizes trapezoidal commutation with Hall effect sensor feedback to achieve two-quadrant BLDC speed control. Speed can be controlled via external analog voltage input, or by using internal hardware settings. These drives do not require software.

Learn more about the EZ Motor Drive here.

Universal Drive

Utilizing advanced four-quadrant control, these drives feature selectable speed, torque or positioning modes, all of which are configured via an intuitive software interface. Users can rely on Hall effect sensor feedback for reliable commutation and optical encoder inputs for precision motion control. ElectroCraft’s Complete Architect software enables easy setup and configuration via USB.

Learn more about the EZ Motor Drive here.

PRO Series

The PRO Series is the most sopisticated series of drives with speed, torque and position control. What sets this series apart is its advanced programmable motion control, powered by ElectroCraft’s Motion Pro Suite software, enabling automated, high-performance servo drive operation. It has several operating modes as a single-axis motion controller, as an intelligent slave executing motion control sequences or as part of a multi-axis distributed motion control network.

Learn more about the EZ Motor Drive here.

Motor drive solutions for any unique need

ElectroCraft DC motor drives are versatile and customizable for high-volume OEM applications. They are used in various industries, including robotics, medical equipment, semiconductor processing and electronics manufacturing. For more information, visit the ElectroCraft website.